Repair PET2001 AKA CMB 3032: Difference between revisions

| Line 62: | Line 62: | ||

Now I can start using the PET! | Now I can start using the PET! | ||

Lets see if I can find a commodore cassette player for it. I do have a dual floppy unit that I can also try now, I don't know if it works, but we will see. | Lets see if I can find a commodore cassette player for it. | ||

I do have a dual floppy unit that I can also try now, I don't know if it works, but we will see. | |||

I will also re-assemble the original speaker system that the previous user had built in. | I will also re-assemble the original speaker system that the previous user had built in. | ||

Revision as of 01:38, 29 July 2017

| Project repair PET2001 (AKA CBM2032) | |

|---|---|

| |

| Een poging tot reparatie van een echte klassieker, de CBM 3032 uit 1977 | |

| Status | In progress |

| Contact | Mahjongg |

| Last Update | 2017-07-29 |

The original first PET, for Personal Electronic Transactor (The "Blue label PET" variant with calculator keys, and a built in tapedeck) was one of the "Trinity", The three first commercial, microprocessor based, "home computers" which were released in 1977 almost simultaneously. They started the microcomputer (personal computer) revolution, and the trinity was the PET 2001 from Commodore, the TRS-80 model 1 from Tandy corporation, and the Apple ][ from Apple computers. According to some this makes the PET the first homecomputer, as it is said it arrived first on the market of these three. But in fact I know of at least several others that came before it that could be called that, for example the SOL-20 came on the market in June 1976, at least a year earlier, but yes it wasn't a mass marketed machine.

Very soon after that launch, Commodore realised they had a winner, and when they had depleted their small supply of surplus calculator keys they used for their launch machines (they were in the calculator business, but had lost out to Texas Instruments) they realised a better keyboard, and more memory was needed (the original blue Label PET only came in an 8K version that used static RAM) , so they removed the built in tapedeck to make room for a larger real keyboard, and released this improved version as the "Commodore Business Machine" or CBM in three types, one with 8K DRAM, one with 16K DRAM and one with 32K DRAM, this last one was called the type 3032, where the 32 stood for the amount of 32K RAM The 8K and 16K machines proved to be less popular, and really only were bought by people who tried to convert them to 32K machines themselves, a practice Commodore actively tried to make impossible by drilling large holes in the place on the board where the second 16K RAM bank was located! See Picture below, where you can see the four large holes drilled in a row though the unused second bank of ram chips in the front of the large PCB:

I have both the later 80-column machine (the 8032) and the original 40-column machine the CBM 3032, the first one works but not the latter one, which sucks as all the good software was written for the 40-column machine, so I'm trying to repair the defective 40-column PET.

repair at Revspace started 11 July 2017

The symptoms are that the system when turned on gives an inverted (all white) picture with only a black blinking cursor, and the picture is very unstable, as if there are large amounts of ripple in the power supply, and it also disappears unless you tap the enclosure. So I had already replaced the massive 23000 MFD (microfarad) 15V DC "Bulk Elco" with screw terminals tie-rapped to the bottom of the case, and a slightly smaller 4700uF 25V axial elco on the main board, but without any change, So probably one of the elco's in the monitor itself has gone bad, I have now removed the monitor (head part) from the PET, and removed another elco from its PCB, next time I will bring a replacement elco, and a new fuse (large size 3/4A 250V slow blow) which I blew due to me stupidly shorting the 18V AC leads leading the the monitor from the very bulky transformer. I will also clean the brightness potentiometer as I think its causing the disappearance of the video due to a bad contact in it.

further repair on monitor 19 July 2017

I removed, cleaned and tested the 100K brightness potmeter, and it was fine, no intermittent contacts. Even though I noted that putting pressure on its axis brought back the picture, but I suspected a cold joint somewhere on the PCB, so I resoldered any and all solder joints, and in the end managed to get a stable picture out of the scope that didn't disappear all the time, but was still shaky. I noted that after a minute or so I saw black stripes in the white picture, and it seemed to become worse as time passed, I had seem this the very first time I turned on the PET too, but now the monitor stayed on it was more obvious. To me it looked like a bad chip somewhere that failed as it was warming up. I decided to do some voltage checking, and to my horror found about 7.5V on first one, and then other LSTTL chips in the from of the board. So there is a power supply fault somewhere, which may explain why when turning the PET off I see a glimpse of the *** COMMODORE BASIC *** initialisation text Perhaps that during the falling of the power voltage, for a moment the display logic starts working.... I don't know if (LS) TTL can withstand 7.5V for very long, but perhaps I'm lucky. I think the PET has two different 5V "zones" each one powered by a different 5V regulator. Perhaps the fault is only in the display logic "zone", and not in the CPU logic "zone". I have to printout the schematic (which I have in electronic form) to check this, then attempt to use a bench power supply to power the display zone. I noticed that the -5V supply voltage was okay.

20 July

I managed to acquire an LM340-5, which is the more precise version of the simple 7805 linear regulator (4.9 to 5.1 volt, instead of 4.8 to 5.2 Volt). In the PET there are two TO-3 versions of the LM340-5 used, but mine has a TO220 package. Should work, as both are 1.0A max (or 1.5A depending on who you ask). I also printed out a technical reference manual, with schematics, and saw that the two LM340-5's used both fed to a different +5V line, but nothing says which chips are fed by one regulator or by the other regulator. Stupidly the net labels are both simply called "+5", a mortal sin with modern CAD systems as CAD software will simply connect both nets together, which in this case I'm sure is NOT true (At least I hope not). Just have to find out with a multimeter which chips are connected to which "+5" net. I only ever saw a system before that used two 7805 Regulators in this way, namely the Acorn Atom, I always thought the Atom was unique in this, but perhaps not, and they stole this idea from the PET. I also noted that the very first PET used not dynamic but static RAM, only later they learned to use 16K x 1 dynamic RAM chips, for which they had to add refresh logic. The schematics of the later PETs with DRAM carry the name "Dynamic PET". LOL.

26 July SUCCESS !

After removing the LM340-5 that I thought was defective, I could connect it to a power supply on its own, and could determine it was indeed defective! So I tried replacing it with an external Lab power supply to see of the part of the board powered by this supply wasn't defective (with the normal supply generating other voltages the board needed, such as +12V and -5V) and would start to draw a lot of current, that wasn't the case, it drew a steady 1A. So I turned on the monitor too, and lo and behold I was greeted with a

*** COMMODORE BASIC 4.8 ***

31743 BYTES FREE

READY.

message! and a blinking cursor. joy!

It seems all the (video) logic, and DRAM powered by the defective LM340-5 has survived!

Unfortunately the PET does not react to keypresses, so we have to do some more work on it, but I really did make progress. The best part was that the text was completely unwavering, so my CRT repair was a good one. Next, try to replace the 6520 PIA that is used for the keyboard.

27 July Keyboard partly works

First I switched the 6520 that drives the keyboard with the one that drives the IEEE bus, it made no change. Secondly I looked and a BCD to decimal decoder that drives the 10 matrix lines of the keyboard, and at its input I saw that the keyboard was being scanned. To make a long story short, it seems the contacts of the keyboard switches have oxidised and closing the contact no longer represents a low enough impedance to overcome the eight 10K pullups. I managed to get the contact for the spacebar to lower from a few kilo ohm to a few hundred ohm by using K60 contact spray an some vigorous rubbing, and so I applied the same treatment to all other key contacts. Unfortunately I had disassembled one key so that I could press its carbonised rubber dome to the pad, and in the process I managed to loose the spring that pushed the key up again. sigh. :-(

I tested the keyboard after re-assembling it (minus the springless key) and the spacebar worked, as did a few others, but on the whole it seems rubbing K60 on the pads isn't helping enough. I guess the keypads will never become as they have once been.

I'm thinking of replacing the 10K pullups with some that are much weaker, say 47K or perhaps even 100K, these still will pull the GPIO (6520 PIA) pins up above logic high level, but even a much weaker contact closure may be enough to bring them below logic low level, not the nicest solution, but I can try if it works. Before the K60 treatment I saw that the GPIO for space only dropped halfway (to about 2.5V) so a five fold decrease in pullup strength should help there. I could also try to replace the BCD to decimal decoder with a new, stronger one, but I don't think its the problem, its just that the keys have worn out.

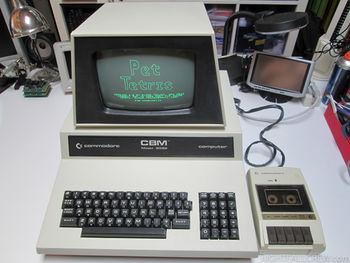

29 July Repair completed, keyboard works 100%

After changing the 10K pullups to 47K, most keys still would not work, and I came convinced that not only were the key-pad fingers worn, but somehow they were also contaminated with something, perhaps the original user was a heavy smoker, or some coke was dripped into the keyboard in the pas. I decided to re-tin the contact fingers of the spacebar (which already worked) and the enter key which did not at all work, even with the weaker pullups, and see what the result was. It was good, both space and enter now worked reliably. So I started on the enormous job of very carefully re-tinning the tiny traces that formed interlocking fingers under each of the eighty or so carbon pads. With the help of some liquid solder flux, a soldering iron set to the exact temperature at which the solder "took" while the glue to which the pads were bonded to the PCB did not give way, and some solder wick to spread out the solder evenly. It was a difficult job, but in the end it all worked out, and after cleaning the PCB thoroughly with flux remover and isopropanol all keys worked again. I temporary replaced the lost spring with a piece of rubber tube.

Now I can start using the PET! Lets see if I can find a commodore cassette player for it.

I do have a dual floppy unit that I can also try now, I don't know if it works, but we will see. I will also re-assemble the original speaker system that the previous user had built in.