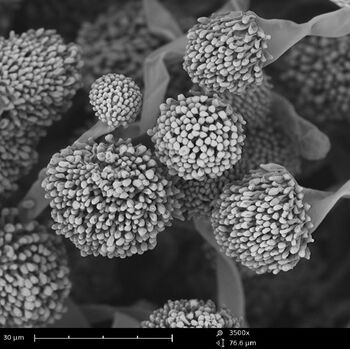

SEM oud

| Project SEM | |

|---|---|

| |

| Getting SEMsational images of chips, materials, and more! | |

| Status | Initializing |

| Contact | User:Shiz, User:Peterbjornx, User:PeterC |

| Last Update | 2019-10-16 |

Background

With the recent improvements to RevSpace's chip analysis infrastructure, we want to take it to the next level and acquire and maintain an actual scanning electron microscope (SEM)! We've found a good candidate and are pending contact with the seller to get confirmation of all the details.

Benefits

- We can image chips with ridiculous clarity

- We can image anything with ridiculous clarity, who needs normal microscopes

- It's a super cool device!

- It'd be the first public usage device of its kind in the Netherlands, and a good opportunity to get people to participate in RevSpace to do any projects requiring it, see #Use_cases!

Requirements

- Initial funding (see #Funding)

- Initial RevSpace resources (space, people willing to set it up)

- Ongoing maintenance (cleaning, occasional Tungsten fillament replacement if heavily used)

- Ongoing RevSpace resources (electricity, maintenance)

Candidate

We are currently looking at a candidate from a seller in a nearby country. It has the following properties:

- Precision: 4.5 nm

- Magnification: up to 300,000x

- Accelerating voltage: up to 30 kV

- Probe current: 1 pA - 1μA

- Pump type: turbo

- Built: early 90's

- Power (peak): 2300W

Additionally, it has the following benefits that certainly sweeten the deal:

- Support for energy-dispersive X-ray spectroscopy (EDX)

- Support for digital imagining

- Confirmed working

- Very extensive manual available

SEM GANG

| Name | Amount | Paid |

|---|---|---|

| Shiz | €2000 | no |

| pbx | €1000 | no |

| PeterC | €x | no |

| merethan | €1000 | no |

| cmpxchg | €1000 | no |

| Morphje | €10 | no |

| Sebastius | €140 | no |

| noopwafel | €300 | no |

| jelle | €50 | no |

| eightdot | €500 | no |

| Peetz0r | €50 | no |

| Total | €6050 |

The preliminary cost estimation as of right now is €7000. A bit over €6000 for the microscope itself, and the remainder for getting it to RevSpace and up and operational. We are looking into minimizing these costs, among others by haggling and finding cheaper options for transport. We are also in the process of running a full cost estimation.

All contributions matter, no matter how big or small!

Use cases!

- Chip reverse engineering

- Chip failure analysis

- Metallurgy

- Detailed material analysis

- Biological analysis (subject to pre-processing depending on kind)

Resources

- SPACE! The size approximates a bigger desk.

- Idea: move the current desk containing the t-shirt press (which can also stored on a shelf and used on the main desks, as it is only used occasionally) and microscope (deprecated) out of the way.

- tshirt press needs a proper sturdy table and it needs to remain relatively clean, so it should live in the main room. The centre-desks and the side desks are NOT suitable (not strong enough. The microscope is NOT deprecated, not even with an SEM present.

- ^ The t-shirt press could sit on the SEM table itself, which is very sturdy. The microscope being deprecated was a quip, but it could be moved to the table leftside of the heavy-duty electronics measuring equipment.

- Idea: move the current desk containing the t-shirt press (which can also stored on a shelf and used on the main desks, as it is only used occasionally) and microscope (deprecated) out of the way.

- Electricity! It's a rather heavy machine on max draw of 2300W.

- If this is problematic for normal usage: charge for use?

- Measure it during the first few uses. Probably not a huge deal.

- If this is problematic for normal usage: charge for use?

- Sound: the roughing pump is rather loud, which you do not want in a normal lounge room.

- Nope, that will make it impossible to remain in the main room.

- Possible to keep it at short distance from the actual machine, so it's possible to put it on the other side of a drilled-through wall.

- That will put it in the werkplaats, which is way to dusty for equipment to survive.

- ^ Maybe making a protective cover for the pump solves this.

- Maintenance! Normal maintenance requires just cleaning and very occasional Tungsten fillament replacement, which is cheap.

- Roughing pump breaks: fairly cheap to replace;

- Turbo pump breaks: moderately expensive but also very hard to break;

- Vacuum failure: SEM has protection against this, would at most be just replacing the O-rings;

- Column breaks: rather expensive, but completely avoidable given good instructions, and there is a good manual for newbies available;

Roadmap/TODO

- Get in contact with seller and confirm condition

- Talk with other (hackerspace) SEM owners, their experiences can come in handy

- Find best way forward for potential resource issues above

- Set up acquisition and maintenance plan

- Get approval from board

Changelog

2019/10/15: found candidate, discussed foundations, started preliminary planning, created project page