Foundry: Difference between revisions

Created page with " {{Project |Name=Foundry |Status=In progress |Contact=Semafoor, Gori }} ==Goal== To make a foundry capable of melting reasonably l..." |

No edit summary |

||

| Line 7: | Line 7: | ||

==Goal== | ==Goal== | ||

To make a foundry capable of melting reasonably large amounts of metal, more specifically aluminium, brass and bronze. In my wildest dreams also cast iron, but that may not be realistic | To make a foundry capable of melting reasonably large amounts of metal, more specifically aluminium, brass and bronze. In my wildest dreams also cast iron, but that may not be realistic | ||

=Furnaces= | |||

==Initial design== | ==Initial design== | ||

| Line 30: | Line 32: | ||

** Waste oil: Motor oil or vegetable oil. (nearly) free to run. easy to run, quite clean when running. Vegetable oil would be CO2-neutral as well. Most hackable fuel (dedicated fuel system and all) | ** Waste oil: Motor oil or vegetable oil. (nearly) free to run. easy to run, quite clean when running. Vegetable oil would be CO2-neutral as well. Most hackable fuel (dedicated fuel system and all) | ||

==Literature and references | ===Build status=== | ||

====Barrel==== | |||

A 60l oil drum has been acquired. It now needs to be separated into a part for the lid and a part for the lower body. The lid needs some reinforcement to be lifted and to keep the refractory in. | |||

The lower body needs a drain hole (in case of crucible failure, to let the molten metal out) and an air intake hole for the burner flame. | |||

====Frame==== | |||

The frame needs to | |||

* support the furnace body | |||

* be strong enough to transport the entire furnace on its wheels | |||

* support the lid lifting and lid rotating mechanism | |||

The wheels for the foundry are probably the first thing to cast using this furnace, as an (easily replaceable) aluminium wheel would be sufficiently heat resistant. | |||

====Burner==== | |||

Depends on whether propane or waste oil is used | |||

====Blower==== | |||

Three blowers are available: | |||

* Low power dual 115V Xerox blower | |||

* medium power domestic heating blower | |||

* reasoably high power forging blower aquired through [[user:Pietdv|Pietdv]] | |||

====Refractory==== | |||

=Molds= | |||

Probably sand casting, see | |||

=Literature and references= | |||

http://backyardmetalcasting.com/ | http://backyardmetalcasting.com/ | ||

http://www.alloyavenue.com/vb/forum.php | http://www.alloyavenue.com/vb/forum.php | ||

Revision as of 10:02, 26 November 2014

| Project Foundry | |

|---|---|

| Status | In progress |

| Contact | [[Project Contact::Semafoor, Gori]] |

| Last Update | 2014-11-26 |

Goal

To make a foundry capable of melting reasonably large amounts of metal, more specifically aluminium, brass and bronze. In my wildest dreams also cast iron, but that may not be realistic

Furnaces

Initial design

Gori made a small foundry out of a soup can, a propane blowtorch and some refractory. This works reasonably well and never fails to gather a crowd. It only melts approximately 0.2 l of aluminium, and this is clearly not enough to do any real work.

Second incarnation

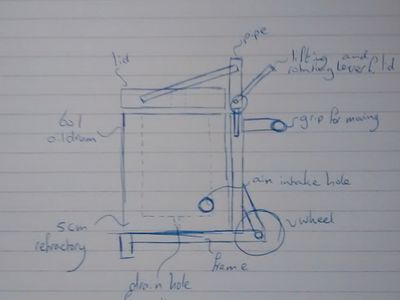

Semafoor is gathering materials to build a second, much larger furnace out of a 60 l oil drum. Should look something like this >.

Key points are:

- Movable on its own wheels because it will be heavy

- A lid to reduce the heat loss at the top (big problem in the soup can furnace

- Incorporated device to lift the lid up and to swing it to the side

- Lid will be mounted on a tube that will slide into a larger tube of the frame

- Lever + Cam to lift the lid a couple of cm, to be clear of the bottom part of the furnace

- Same lever will be used to swing the lid sideways

- about 5 cm of refractory all around. Probably a bit more on the lid for rigidity

- Electric blower to provide more air for combustion > more fuel > more heat

- Fuel: Not sure yet. Possiblities are:

- Coal: Low initial investment. Needs a specific design to get the air at the right places. Dirty operation

- Propane: moderate initial investment. Relatively expensive to run. Easy to run. Cleanest fuel.

- Waste oil: Motor oil or vegetable oil. (nearly) free to run. easy to run, quite clean when running. Vegetable oil would be CO2-neutral as well. Most hackable fuel (dedicated fuel system and all)

Build status

Barrel

A 60l oil drum has been acquired. It now needs to be separated into a part for the lid and a part for the lower body. The lid needs some reinforcement to be lifted and to keep the refractory in. The lower body needs a drain hole (in case of crucible failure, to let the molten metal out) and an air intake hole for the burner flame.

Frame

The frame needs to

- support the furnace body

- be strong enough to transport the entire furnace on its wheels

- support the lid lifting and lid rotating mechanism

The wheels for the foundry are probably the first thing to cast using this furnace, as an (easily replaceable) aluminium wheel would be sufficiently heat resistant.

Burner

Depends on whether propane or waste oil is used

Blower

Three blowers are available:

- Low power dual 115V Xerox blower

- medium power domestic heating blower

- reasoably high power forging blower aquired through Pietdv

Refractory

Molds

Probably sand casting, see