InductionHeater: Difference between revisions

No edit summary |

Added Inverter schematic |

||

| Line 12: | Line 12: | ||

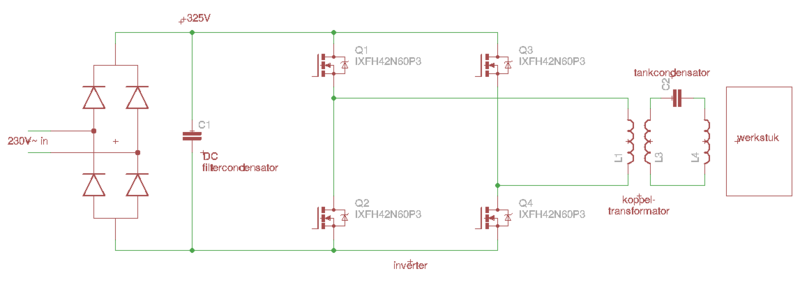

==Inverter circuit== | ==Inverter circuit== | ||

Smeding | Smeding came up with the following circuit: | ||

[[File:Induction_heater_system.png|800px]] | |||

Values of all components are to follow shortly. | |||

The accompanying BOM looks something like this: | |||

{|class="wikitable" | {|class="wikitable" | ||

Revision as of 11:26, 8 September 2014

| Project InductionHeater | |

|---|---|

| Status | Initializing |

| Contact | smeding, gori |

| Last Update | 2014-09-08 |

Idea is to make a 3kW induction spool to smelt metals and heat steel for forging. For examples see :

Inverter circuit

Smeding came up with the following circuit:

Values of all components are to follow shortly. The accompanying BOM looks something like this:

| Component | cost |

|---|---|

| Bridge rectifier | €2.56 |

| switching transistor | €22.92 |

| Tank capacitors | 20.50 |

| DC link filter capacitor | €23.14 |

| Gate driver | €7.06 |

| Couple transformer Toroid | €20 (est.) |

| Gate drive transormer toroid | €3 |

| Estimate for components killed (see below) | €60 |

| Total | €160 |

Based on Smedings estimate Obviously, some parts may die a gruesome death during construction and testing. Worst case estimate is that the switching transistor and the driver will die twice, adding an amount of €60 to the BOM before we have a working machine.

Additional hardware

In addition to the inverter circuit, at least the following things are needed to make a working induction heater

| Component | cost | Possible sources | requirements |

|---|---|---|---|

| Coil 1 small diameter for smelting | € 15 ? | Gas tubing, car brake tubing | Copper. Sufficient copper area to handle the current. Sufficient inner area + diameter to allow for effective cooling |

| Coil 2 large diameter, 30cm for forging, between 5 and 10m | € 25 - 50 | Gas tubing, 15 mm car brake tubing | Copper. Sufficient copper area to handle the current. Sufficient inner area + diameter to allow for effective cooling |

| heat exchanger | €15 ? | Car junkyard | Unsure how much heat needs to be removed and at what temperatures. Worst Case would be 3 kW. A car radiator is probably good (cheap, sufficient power and an integrated fan) |

| Pump | €20 | Possibly a pump from a domestic heater (CV). Buy for around €20 on Marktplaats | Have to check whether or not normal sizes create sufficient flow through small diameter coil tubing |

| Electrical connections and wiring | € 20 | Battery connections form scrapped cars? | How much current do we expect, and how long do the wires have to be? how do we connect these to the coil tubing (Earth blocks? |

| Tubes and other cooling connectors | 15€ | ||

| ... | |||

| Total cost | € 85 (incomplete) |

Total cost

| cost | |

|---|---|

| Inverter | €160 |

| Hardware | €85 |

| Total | €245 |

Now we need financing. The current total is €245, and that isn't complete so far (although it may get close)

Pledges: