InductionHeater: Difference between revisions

(waarschuwing) |

(Page rewrite with actual BOM!) |

||

| Line 1: | Line 1: | ||

{{Project | {{Project | ||

|Name=InductionHeater | |Name=InductionHeater | ||

|Status= | |Status=In progress | ||

|Contact= smeding, gori | |Contact= smeding, gori | ||

}} | }} | ||

We're working on an induction heater that can be used to heat anything conductive to high temperatures. The plan is to try to use it for forging steel and melting aluminium. | |||

Here are some examples of what a device like this is capable of: | |||

* [http://www.youtube.com/watch?v=0HdbKKvOiWU] | * [http://www.youtube.com/watch?v=0HdbKKvOiWU] | ||

* [http://www.youtube.com/watch?v=l7fArOvXhQY] | * [http://www.youtube.com/watch?v=l7fArOvXhQY] | ||

==Specs== | |||

* Input power: 3.5kVA, standard single-phase mains | |||

* Frequency: 10 - 100 kHz | |||

==Inverter circuit== | ==Inverter circuit== | ||

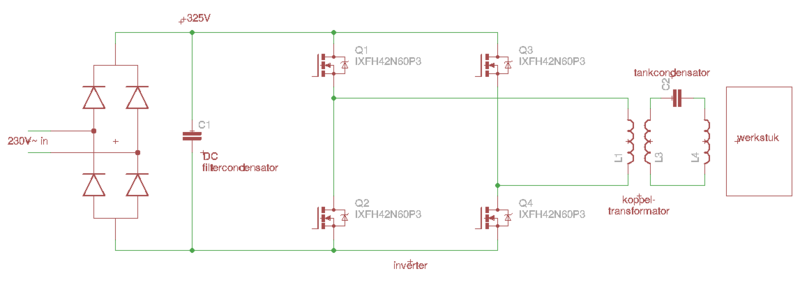

The basic power system looks as follows: | |||

[[File:Induction_heater_system.png|800px]] | [[File:Induction_heater_system.png|800px]] | ||

230V mains input is rectified, then filtered slightly and chopped up into a variable-frequency square wave (or modified sine wave) using an H-bridge made of IGBTs. This is fed into a coupling transformer, which turns this high voltage, (relatively) low-current waveform into a higher-current, lower-voltage one more suitable for the system. This is connected to a series-resonant circuit comprised of the heating coil and a tank capacitor. | |||

The resonant frequency changes depending on workpiece geometry, coil geometry, workpiece temperature, etc. etc. so this needs to be tracked by a controller. | |||

The secondary side of the transformer dissipates a lot of power (there are potentially hundreds of ampères flowing there, so fairly large ohmic losses) and will need to be water-cooled to prevent it from getting too hot. | |||

== BOM == | |||

Some of the components have already been scrounged together. Thanks to benadski for acquiring an induction cooktop that contained many useful parts! | |||

{|class="wikitable" | {|class="wikitable" | ||

!Component | !Component | ||

! | !Cost | ||

!Comments | |||

|- | |- | ||

|Bridge rectifier | |Bridge rectifier | ||

| | | | ||

|Salvaged from cooktop | |||

|- | |- | ||

| | |inverter IGBTs | ||

| | | | ||

|Salvaged from cooktop | |||

|- | |- | ||

|Tank capacitors | |Tank capacitors | ||

| | | | ||

|Salvaged from cooktop | |||

|- | |- | ||

|DC link filter capacitor | |DC link filter capacitor | ||

| | | | ||

|Salvaged from cooktop | |||

|- | |- | ||

|Gate | |Gate drive transformers | ||

| | | | ||

|Salvaged from cooktop | |||

|- | |- | ||

| | |Coupling transformer core(s) | ||

| | |€42 | ||

|http://www.aliexpress.com/item/100mm-x-65mm-x-20mm-Ferrite-Rings-Toroid-for-Filters-Coils/879528762.html, we need 3 of these for enough core area | |||

|- | |- | ||

| | |Litz wire for transformer primary | ||

| | | | ||

|Salvaged from cooktop | |||

|- | |- | ||

| | |Copper tubing, 15mm OD * 5m | ||

| | |€30 | ||

|Conservative estimate from hardware store -- can probably do better. Will need more than 5m for larger work coil. | |||

|- | |- | ||

| | |Copper pipe compression couplings 15mm * 2 | ||

| | |€12 | ||

| | |Can probably do better | ||

|- | |- | ||

| | |Water cooling pump | ||

| | |€5 | ||

| | |Cheap brushless water pumps abound on eBay; e.g. http://www.ebay.com/itm/321431156285 | ||

|- | |- | ||

| | |Water cooling connections | ||

| | |? | ||

| | |Need to find best solution | ||

|- | |- | ||

|Water cooling radiator | |||

| | |? | ||

| | |Car engine radiator goes €10 - €20 on Marktplaats. Possibly from scrapyard? | ||

|Car | |||

|- | |- | ||

| | |Gate driver *4 | ||

| | |€5 | ||

| | |e.g. http://nl.farnell.com/microchip/tc4420coa/ic-driver-mosfet-6a-smd-soic8/dp/1292283 | ||

|- | |- | ||

| | |Control electronics | ||

| | |€10 | ||

| | |Microcontroller, displays, assorted resistors&capacitors | ||

|- | |- | ||

|'''Total''' | |'''Total''' | ||

| | |€104 | ||

|} | |} | ||

== Pledges == | |||

So far, the following has been pledged: | |||

* [[Gori]]: 50 euro | * [[Gori]]: 50 euro | ||

* [[Flok]]: 10 euro | * [[Flok]]: 10 euro | ||

| Line 135: | Line 103: | ||

* [[bertrik]]: €10 | * [[bertrik]]: €10 | ||

* Semafoor: €20 (more if the project is better defined) | * Semafoor: €20 (more if the project is better defined) | ||

Total pledges: €160 | |||

Revision as of 02:17, 1 October 2014

| Project InductionHeater | |

|---|---|

| Status | In progress |

| Contact | smeding, gori |

| Last Update | 2014-10-01 |

We're working on an induction heater that can be used to heat anything conductive to high temperatures. The plan is to try to use it for forging steel and melting aluminium.

Here are some examples of what a device like this is capable of:

Specs

- Input power: 3.5kVA, standard single-phase mains

- Frequency: 10 - 100 kHz

Inverter circuit

The basic power system looks as follows:

230V mains input is rectified, then filtered slightly and chopped up into a variable-frequency square wave (or modified sine wave) using an H-bridge made of IGBTs. This is fed into a coupling transformer, which turns this high voltage, (relatively) low-current waveform into a higher-current, lower-voltage one more suitable for the system. This is connected to a series-resonant circuit comprised of the heating coil and a tank capacitor.

The resonant frequency changes depending on workpiece geometry, coil geometry, workpiece temperature, etc. etc. so this needs to be tracked by a controller.

The secondary side of the transformer dissipates a lot of power (there are potentially hundreds of ampères flowing there, so fairly large ohmic losses) and will need to be water-cooled to prevent it from getting too hot.

BOM

Some of the components have already been scrounged together. Thanks to benadski for acquiring an induction cooktop that contained many useful parts!

| Component | Cost | Comments |

|---|---|---|

| Bridge rectifier | Salvaged from cooktop | |

| inverter IGBTs | Salvaged from cooktop | |

| Tank capacitors | Salvaged from cooktop | |

| DC link filter capacitor | Salvaged from cooktop | |

| Gate drive transformers | Salvaged from cooktop | |

| Coupling transformer core(s) | €42 | http://www.aliexpress.com/item/100mm-x-65mm-x-20mm-Ferrite-Rings-Toroid-for-Filters-Coils/879528762.html, we need 3 of these for enough core area |

| Litz wire for transformer primary | Salvaged from cooktop | |

| Copper tubing, 15mm OD * 5m | €30 | Conservative estimate from hardware store -- can probably do better. Will need more than 5m for larger work coil. |

| Copper pipe compression couplings 15mm * 2 | €12 | Can probably do better |

| Water cooling pump | €5 | Cheap brushless water pumps abound on eBay; e.g. http://www.ebay.com/itm/321431156285 |

| Water cooling connections | ? | Need to find best solution |

| Water cooling radiator | ? | Car engine radiator goes €10 - €20 on Marktplaats. Possibly from scrapyard? |

| Gate driver *4 | €5 | e.g. http://nl.farnell.com/microchip/tc4420coa/ic-driver-mosfet-6a-smd-soic8/dp/1292283 |

| Control electronics | €10 | Microcontroller, displays, assorted resistors&capacitors |

| Total | €104 |

Pledges

So far, the following has been pledged:

- Gori: 50 euro

- Flok: 10 euro

- Walter: 50 евра

- FooBar: €20

- bertrik: €10

- Semafoor: €20 (more if the project is better defined)

Total pledges: €160