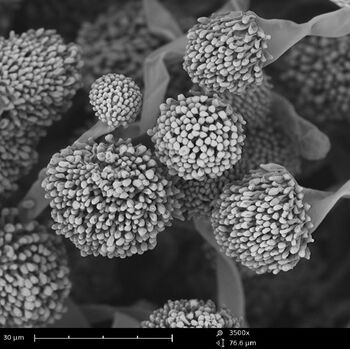

SEM oud

| Project SEM | |

|---|---|

| |

| Getting SEMsational images of chips, materials, and more! | |

| Status | Abandoned |

| Contact | User:Shiz, User:Peterbjornx, User:PeterC |

| Last Update | 2021-11-20 |

Cancelled

Because of a new project by the same group of people this project has been superseded by Absolute SEM. This new project is a private initiative of User:Peterbjornx, User:Shiz, User:PeterC and User:noopwafel, and will still be closely cooperating with RevSpace, but to avoid the political aspect of a large group owning a piece of expensive equipment, it was decided to keep that within this group of friends.

Background

With the recent improvements to RevSpace's chip analysis infrastructure, we want to take it to the next level and acquire and maintain an actual scanning electron microscope (SEM)! We've found a good candidate and are pending contact with the seller to get confirmation of all the details.

Benefits

- We can image chips with ridiculous clarity

- We can image anything with ridiculous clarity, who needs normal microscopes

- It's a super cool device!

- It'd be the first public usage device of its kind in the Netherlands, and a good opportunity to get people to participate in RevSpace to do any projects requiring it, see #Use_cases!

Requirements

- Initial funding (see #Funding)

- Initial RevSpace resources (space, people willing to set it up)

- Ongoing maintenance (cleaning, occasional Tungsten fillament replacement if heavily used)

- Ongoing RevSpace resources (electricity, maintenance)

Use cases!

- Chip reverse engineering

- Chip failure analysis

- Metallurgy

- Detailed material analysis

- Biological analysis (subject to pre-processing depending on kind)

Candidate

We are currently looking at a candidate from a seller in a nearby country. It has the following properties:

- Precision: 4.5 nm

- Magnification: up to 300,000x

- Accelerating voltage: up to 30 kV

- Probe current: 1 pA - 1μA

- Pump type: turbo

- Built: early 90's

- Power (peak): 2300W

Additionally, it has the following benefits that certainly sweeten the deal:

- Support for energy-dispersive X-ray spectroscopy (EDX)

- Support for digital imagining

- Confirmed working

- Very extensive manual available

SEM GANG

These entries are kept only for historical reasons and are in no way related to the Absolute SEM project.

| Name | Amount | Paid |

|---|---|---|

| Shiz | €2000 | no |

| pbx | €1000 | no |

| PeterC | €300 | no |

| merethan | €1000 | no |

| cmpxchg | €1000 | no |

| Morphje | €10 | no |

| Sebastius | €50 | no |

| noopwafel | €300 | no |

| jelle | €50 | no |

| eightdot | €500 | no |

| smeding | €200 | no |

| Total | €6460 |

The preliminary cost estimation as of right now is €7000. A bit over €6000 for the microscope itself, and the remainder for getting it to RevSpace and up and operational. We are looking into minimizing these costs, among others by haggling and finding cheaper options for transport. We are also in the process of running a full cost estimation.

All contributions matter, no matter how big or small!

Requirements

Location-wise

- SPACE! The size approximates a bigger desk.

- Idea: move the current desk containing the t-shirt press (which can also stored on a shelf and used on the main desks, as it is only used occasionally) and microscope (deprecated) out of the way.

- tshirt press needs a proper sturdy table and it needs to remain relatively clean, so it should live in the main room. The centre-desks and the side desks are NOT suitable (not strong enough. The microscope is NOT deprecated, not even with an SEM present.

- The t-shirt press could sit on the SEM table itself, which is very sturdy. The microscope being deprecated was a quip, but it could be moved to the table leftside of the heavy-duty electronics measuring equipment.

- (pbx:) The binoc microscope is useful for sample prep as well and should sit on the SEM desk, the t-shirt press does not require permanent setup so i think it could be stored on a shelf and be used on the SEM desk/some other sturdy place when needed.

- The t-shirt press could sit on the SEM table itself, which is very sturdy. The microscope being deprecated was a quip, but it could be moved to the table leftside of the heavy-duty electronics measuring equipment.

- tshirt press needs a proper sturdy table and it needs to remain relatively clean, so it should live in the main room. The centre-desks and the side desks are NOT suitable (not strong enough. The microscope is NOT deprecated, not even with an SEM present.

- Idea: move the current desk containing the t-shirt press (which can also stored on a shelf and used on the main desks, as it is only used occasionally) and microscope (deprecated) out of the way.

- Electricity! It's a rather heavy machine on max draw of 2300W.

- If this is problematic for normal usage: charge for use?

- Measure it during the first few uses. Probably not a huge deal.

- If this is problematic for normal usage: charge for use?

- Sound: the roughing pump is rather loud, which you do not want in a normal lounge room.

- Nope, that will make it impossible to remain in the main room.

- Possible to keep it at short distance from the actual machine, so it's possible to put it on the other side of a drilled-through wall.

- That will put it in the werkplaats, which is way to dusty for equipment to survive.

- That will be no problem for this kind of pump, which is mostly sealed off except for the exhaust. If needed we can make a protective cover.

- That will put it in the werkplaats, which is way to dusty for equipment to survive.

Transport

Current candidate is in a nearby country within driving distance.

- Transport company (land/sea)

- Benefits: cheaper when you have no access to a van, don't have to worry about packing it up

- Downsides: need to pick a company with clear experience in packing up lab equipment, or hire separate packing company, may take long to arrive

- Pick-up

- Benefits: cheaper when you have access to a van, quickest to do, guaranteed done properly, combinable with inspection trip

- Downsides: significant effort and stress, costs (van + gas + hotel), have to pack it up ourselves

Maintenance

We can divide SEM maintenance in two rough parts: regular (consumables, cleaning) and irregular (part replacement).

Regular maintenance requires:

- Filament, depending on SEM type.

- Tungsten: semi-regular (every 100 hours) need for replacement, but cheap (€80-100 for 10 used filaments)

- CeB6/LaB6: rare (every 1000-1500) need for replacement, but replacement is expensive and needs specialized knowledge

- Pump oil, depending on SEM type.

- Roughing pump oil: always needed, type depends on pump but generally not very expensive (€20-30/L): replace every 1-2 years with non-constant use

- Vacuum dessicator

- Maybe we can use the vacuum pan for this?

- Dry nitrogen

Irregular maintenance, breakages, include:

- Roughing pump breaks: fairly cheap to replace, should not break; ( E 100+ )

- Turbo pump breaks: moderately expensive, should not break unless badly abused; (E 500-1000)

- Vacuum failure: depends on SEM type:

- Modern SEMs have protection against this, would at most be just replacing the O-rings

- Without protection, may break the column (see below)

- The SEM we are currently considering has interlocks to prevent damage

- Column breaks: expensive, requires specialty parts

Help wanted

We would love assistance, feedback, and involvement. If you like the idea and have knowledge to contribute, please by all means contact us! Specific knowledge that would be useful includes:

- Transport options and contacts

- If we decide to pick it up ourselves we will need a van with tail lift: if you have one/know someone who does, please tell us.

- SEM analysis and maintenance

- (Vacuum) pump analysis and maintenance

- X-ray analysis

- Interesting projects and hackability

Roadmap/TODO

- Get in contact with seller and confirm condition

- Talk with other (hackerspace) SEM owners, their experiences can come in handy

- Find best way forward for potential resource issues above

- Set up acquisition and maintenance plan

- Get approval from board

Changelog

2019/10/15: found candidate, discussed foundations, started preliminary planning, created project page

2019/10/16: got into contact with seller and acting servicing company when it was in operation; expecting to receive more complete details within the next few days

2019/10/17: got response from servicing company, they have last maintained the machine in 2015 and do not have service logs; they do not support the model in question anymore, contacting seller again for physical service logs of the machine.

2019/11/04: UK seller has not replied yet, project contacts have been moderately too busy with life stuff the past two weeks. pursuing UK seller again, else focusing on our alternative options for SEMs. alternatives have been considered, roughly three realistic offers are being looked at: also open to other offers!

Bibliography

General information

Public logs