Vacuumpomp: Difference between revisions

mNo edit summary |

|||

| Line 24: | Line 24: | ||

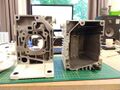

Polishedgasketsurfaces.jpg|Freshly polished gasket surfaces of pump main mount and housing | Polishedgasketsurfaces.jpg|Freshly polished gasket surfaces of pump main mount and housing | ||

Shaftsealdriver.jpg|Shaft seal driver. This tool makes it harder to screw up when installing new shaft seals. | Shaftsealdriver.jpg|Shaft seal driver. This tool makes it harder to screw up when installing new shaft seals. | ||

Gas_ballast_seal.jpg|Old gas ballast seal next to its replacement | |||

</gallery> | </gallery> | ||

| Line 29: | Line 30: | ||

For those who wish to replace the shaft seals without being extorted by Leybold, they are regular FKM GR 15x24x6.5 SS 304 spring oil seals. Available as a general commodity item. | For those who wish to replace the shaft seals without being extorted by Leybold, they are regular FKM GR 15x24x6.5 SS 304 spring oil seals. Available as a general commodity item. | ||

Do not try to replace the gas ballast seal unless absolutely necessary. It is very hard to remove from the deep, blind hole and the seal incorporates an internal metal ring, making cutting the seal out impossible. See gallery photo above. It took me three hours to remove it without damaging the seat, with a combination of solvents, a scalpel and a hemostat. Don't be me, leave it be. | |||

Revision as of 17:33, 21 July 2021

| Project Vacuumpomp | |

|---|---|

| Rebuilding a vacuum pump | |

| Status | In progress |

| Contact | thomas |

| Last Update | 2021-07-21 |

Leybold Trivac D8B

We need a roughing pump for our turbos. I bought this unit a while ago, and it works, but it also makes funny noises.

Plan

It needs to be opened up. I may have to fabricate and/or purchase some new parts to get it back to a more usable state.

Teardown / Rebuild

-

Fully disassembled pump module

-

First and second stage vanes

-

First stage vane in pump module segment

-

Original busted gasket and temporary laser cut silicone replacement

-

Freshly polished gasket surfaces of pump main mount and housing

-

Shaft seal driver. This tool makes it harder to screw up when installing new shaft seals.

-

Old gas ballast seal next to its replacement

Link to the STL for the shaft seal driver.

For those who wish to replace the shaft seals without being extorted by Leybold, they are regular FKM GR 15x24x6.5 SS 304 spring oil seals. Available as a general commodity item.

Do not try to replace the gas ballast seal unless absolutely necessary. It is very hard to remove from the deep, blind hole and the seal incorporates an internal metal ring, making cutting the seal out impossible. See gallery photo above. It took me three hours to remove it without damaging the seat, with a combination of solvents, a scalpel and a hemostat. Don't be me, leave it be.