Designing an enclosure for RhoCoCo: Difference between revisions

| (3 intermediate revisions by the same user not shown) | |||

| Line 3: | Line 3: | ||

|Picture=RhoCoCo 3D preview rendering with slanted keyboard 2.PNG | |Picture=RhoCoCo 3D preview rendering with slanted keyboard 2.PNG | ||

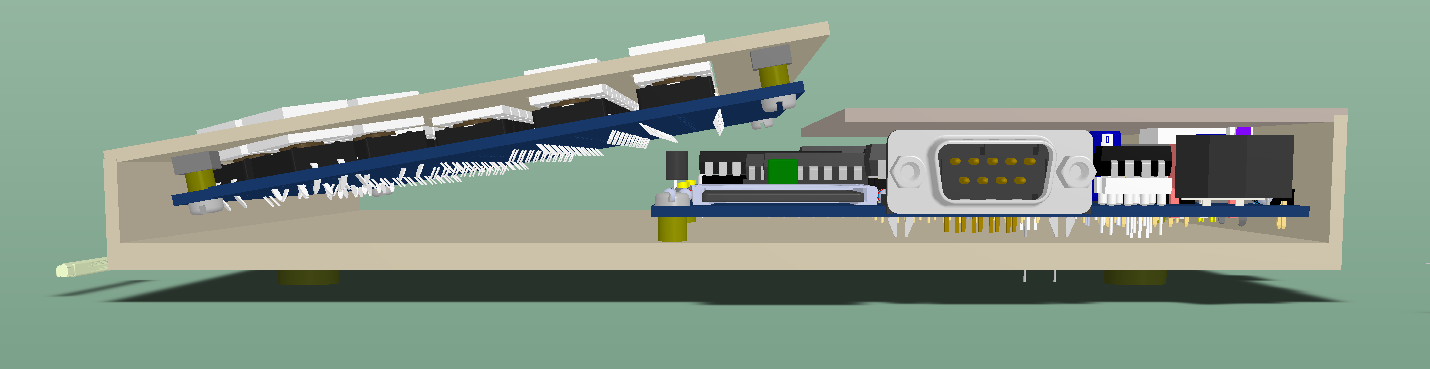

|Omschrijving=Now that the "motherboard", and the keyboard of the Retro Home Color Computer are finished, it is time to think about the various options for its enclosure (case). Here is one option, a case out of laser-cut wood, with a slanted keyboard (C64C style) and curved top made by cutting slits in the wood so that it becomes bendable. | |Omschrijving=Now that the "motherboard", and the keyboard of the Retro Home Color Computer are finished, it is time to think about the various options for its enclosure (case). Here is one option, a case out of laser-cut wood, with a slanted keyboard (C64C style) and curved top made by cutting slits in the wood so that it becomes bendable. | ||

|Status= | |Status=In progress | ||

|Contact=Mahjongg | |Contact=Mahjongg | ||

}} | }} | ||

| Line 11: | Line 11: | ||

== This is a page about the design of an enclosure for the RhoCoCo Retro Home-computer == | == This is a page about the design of an enclosure for the RhoCoCo Retro Home-computer == | ||

Main article is here: https://revspace.nl/Designing_the_RhoCoCo_Retro_Home_COlor_COmputer_hardware | |||

Initially I thought that the simplest solution would be to have the keyboard and motherboard on the same "plane", like the ZX80 and ZX81, and simply mount both on a plank of wood. I even considered using a single PCB for both, just like the ZX80/ZX81, but then the PCB would have become about three times larger, and all of it would be a dual-sided PCB, where I was convinced that the keyboard could be routed on a much cheaper single sided PCB. And like my ZX81+35 ZX-81 clone they could connect together with simple angled pin-header connectors (male and female). | Initially I thought that the simplest solution would be to have the keyboard and motherboard on the same "plane", like the ZX80 and ZX81, and simply mount both on a plank of wood. I even considered using a single PCB for both, just like the ZX80/ZX81, but then the PCB would have become about three times larger, and all of it would be a dual-sided PCB, where I was convinced that the keyboard could be routed on a much cheaper single sided PCB. And like my ZX81+35 ZX-81 clone they could connect together with simple angled pin-header connectors (male and female). | ||

| Line 35: | Line 37: | ||

Otherwise I have to design the case so that the holes are open on top, so that I can "drop-in" the PCB. But as I said that means the shape of the two case halves will become a lot more complex. | Otherwise I have to design the case so that the holes are open on top, so that I can "drop-in" the PCB. But as I said that means the shape of the two case halves will become a lot more complex. | ||

== 15 december, 2018 corrected 3D preview of keyboard with data from gerber files of keyboard PCB == | == 15 december, 2018 corrected 3D preview of keyboard with data from gerber files of keyboard PCB == | ||

| Line 62: | Line 63: | ||

[[File:RhoCoCo 3D preview rendering with slanted keyboard.PNG]] | [[File:RhoCoCo 3D preview rendering with slanted keyboard.PNG]] | ||

== 8 | == January 8, 2019 imagined a wooden case with curved top plate == | ||

I imagined that the top plate could be made curved, with slits cut into the wood, and updated the 3D picture to an impression of how such a wooden enclosure could look like | I imagined that the top plate could be made curved, with slits cut into the wood, and updated the 3D picture to an impression of how such a wooden enclosure could look like | ||

The picture on top, now shows this 3D impression. | The picture on top, now shows this 3D impression. | ||

| Line 72: | Line 73: | ||

I also still have to find a solution that works for inserting the connectors, and switch, on the main PCB through holes in the back and the side. Perhaps I can make a cardboard model to check how to do this in practice. I tend to think the best solution is still to split the case in two halves so that the split-line runs horizontally through the center of the parts of the connectors that stick through the case, so you can lay the main-board in the bottom half, and cover the top half the protruding parts with the top half of the enclosure. This means more complexity in the design, but is probably the only acceptable way to do it, without using separate plates, or over-sized holes. Especially the protruding switch might become a problem. | I also still have to find a solution that works for inserting the connectors, and switch, on the main PCB through holes in the back and the side. Perhaps I can make a cardboard model to check how to do this in practice. I tend to think the best solution is still to split the case in two halves so that the split-line runs horizontally through the center of the parts of the connectors that stick through the case, so you can lay the main-board in the bottom half, and cover the top half the protruding parts with the top half of the enclosure. This means more complexity in the design, but is probably the only acceptable way to do it, without using separate plates, or over-sized holes. Especially the protruding switch might become a problem. | ||

== January 17, 2019 checked 3mm wood thickness combined with 5.8mm high brass standoffs == | |||

To check if the keys with keytops are high enough when I use 5.8mm high brass spacers, and 3mm thick wood, I made this virtual detail: | |||

[[File:Rhococo keys detail, with 3mm thick wood.PNG|500px]] | |||

As you can see the height is fine, even when the button is pressed (left button is virtually pressed in above detail). | |||

As you can see the keytops now have rounded edges, like the real ones. The main picture of the page is also updated with these softer keytops, although the difference is small, it still looks nicer, and more "real". Unfortunately I see no way to put any text on the 3D rendered keytops, but I'm still happy with how this 3D rendered preview looks. | |||

[[Category:RhoCoCo]] | [[Category:RhoCoCo]] | ||

Latest revision as of 12:22, 24 January 2019

| Project The design of an enclosure for RhoCoCo | |

|---|---|

| |

| Now that the "motherboard", and the keyboard of the Retro Home Color Computer are finished, it is time to think about the various options for its enclosure (case). Here is one option, a case out of laser-cut wood, with a slanted keyboard (C64C style) and curved top made by cutting slits in the wood so that it becomes bendable. | |

| Status | In progress |

| Contact | Mahjongg |

| Last Update | 2019-01-24 |

This is a page about the design of an enclosure for the RhoCoCo Retro Home-computer

Main article is here: https://revspace.nl/Designing_the_RhoCoCo_Retro_Home_COlor_COmputer_hardware

Initially I thought that the simplest solution would be to have the keyboard and motherboard on the same "plane", like the ZX80 and ZX81, and simply mount both on a plank of wood. I even considered using a single PCB for both, just like the ZX80/ZX81, but then the PCB would have become about three times larger, and all of it would be a dual-sided PCB, where I was convinced that the keyboard could be routed on a much cheaper single sided PCB. And like my ZX81+35 ZX-81 clone they could connect together with simple angled pin-header connectors (male and female).

The problem with this approach is that many of the components on the main PCB are much higher than the height of the buttons on the keyboard. This means that (with a case made of thin wood or plastic plate) the "motherboard" cant fit when connected with pin-headers, when you want to extend the top plate of the enclosure, (the plate that fits on top of the keyboard) all the way to the back of the enclosure, like the picture in the top right.

It also prevents that you can mount the keyboard on a slight slope, although straight (strictly horizontal) keyboards are normal for laptops. So I don see the need for RhoCoCo to have a sloped keyboard.

The ZX80 (and ZX81) have a heightened part behind the keyboard sloping up to the back, where the highest parts are, but for simplicity a simple rectangular case seems simpler, when you make a case out of laser-cut plastic plate, which seems the cheapest option.

After some thought, I decided that the simplest mechanically stable solution would be to mount, (screw) the keyboard to a keyboard top-plate, and then either mount the main board, with a height off-set also to the top plate, or mount the main board on the bottom, and connect keyboard and main board together with a flat-cable, in Sinclair Spectrum style. The first method would become a problem when you want to add an extension board, and more importantly would make the enclosure having holes for the connectors, switches and SD-card much more complex, as the connectors on two edges of the PCB makes it possible to simply have corresponding holes in the back and side walls of the "box" into which you can mount the main board. If that isn't possible, you have to have an enclosure that is shaped so that if follows either the top half or bottom half of the connector (etc) holes, possible, but not as simple to design. Therefore my first choice would be the second method, a simple box, with a top-half with the keyboard (and speaker) and a bottom half into which the main board is mounted, and a simple flex cable to connect both.

I have determined the parts on the main board need a height of 14mm above them.

The keyboard PCB must be modified, with some PCB material removed from the front corners of the PCB, so that there can be plastic in these corners to screw the top cover to the bottom, using screws in the four corners of the case (four screw-holes in the four corners of the bottom of the case). The top right screw-hole in the main PCB can stay, as the screw-hole can be used for one of the four screws that will be used. three smaller screws will be used to mount the main PCB to the bottom half, and four small screws will be used to mount the keyboard PCB to the top. I added new holes as where the original two front holes were a part of the PCB must be removed. I believe four screws are enough, as the keyboard PCB is relatively tiny.

There is the additional problem of placing the main PCB with connectors on two edges, into the bottom PCB, I remember that on the C64 they handled this mechanical problem by having a separate plate that could be mounted over the switch and power and joystick ports, but that is a too complex solution.

I will try with a model if its possible to have (perhaps slightly enlarged) connector holes in two opposite corner sides, in such a way that you can mount the main PCB, with connectors and such, without any plastic blocking the insertion of the PCB. Maybe I have to create a cardboard mock-up to see if that works.

Otherwise I have to design the case so that the holes are open on top, so that I can "drop-in" the PCB. But as I said that means the shape of the two case halves will become a lot more complex.

15 december, 2018 corrected 3D preview of keyboard with data from gerber files of keyboard PCB

I took the gerber output of the real keyboard PCB, and with it I made some corrections in the altium 3D preview data of the keyboard, so I can design a keyboard top plate that has holes in the exact right places. Now that I have a corrected altium design I have also updated the 3D previews.

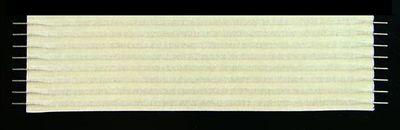

Keyboard and main PCB can be connected with special 5cm long flat cables such as 6-lead Farnell #2598863 (€ 3,3446) plus 8-lead #2599314 (4,0295), but more than 7 euro is a bit too luxurious a solution IMHO.

Instead I will use a 7.62 cm long flexstrip the FSN-23A-15, (farnell order code #1310363) which is much cheaper (@ € 2,74) this is the price for both strips, as we can cut the 15 lead strip into an 8 and a 6 lead parts, We can then solder in the strips to the keyboard, and plug the other ends in to two female headers on the main PCB.

An example of the kind of ribbon cable I have in mind:

wire thickness of the round ends = 0.51mm, length of wire end = 3.18mm. Meaning they will mate with samtec precision machined socket strips.

19 december 2018, investigated a design with a slanted keyboard

Made a 3D model of the keyboard PCB, mounted to a 2mm thick plate with brass spacers (M3 brass screw in spacers, 5.8mm long) the spacers are glued into pieces of plastic, glued to the plate underneath the four screw holes in the PCB, so that the keyboard is hanging on the underside of the plate. This model was slanted 10 degrees so that the main PCB could be partly shoved under it.

A side view of it was generated, and that looks like this:

January 8, 2019 imagined a wooden case with curved top plate

I imagined that the top plate could be made curved, with slits cut into the wood, and updated the 3D picture to an impression of how such a wooden enclosure could look like The picture on top, now shows this 3D impression.

Note that this preview assumed that the default thickness of the wood was 2.0mm, it isn't! The default is thickness is 3mm! This affects the design of the enclosure, especially things like how deep the keys stick out above the top plate when using 5.8mm brass spacers, but also other dimensions, like how much connectors stick out, and the bent ratio of the curved sections.

I will make the necessary changes to the virtual keyboard design.

I also still have to find a solution that works for inserting the connectors, and switch, on the main PCB through holes in the back and the side. Perhaps I can make a cardboard model to check how to do this in practice. I tend to think the best solution is still to split the case in two halves so that the split-line runs horizontally through the center of the parts of the connectors that stick through the case, so you can lay the main-board in the bottom half, and cover the top half the protruding parts with the top half of the enclosure. This means more complexity in the design, but is probably the only acceptable way to do it, without using separate plates, or over-sized holes. Especially the protruding switch might become a problem.

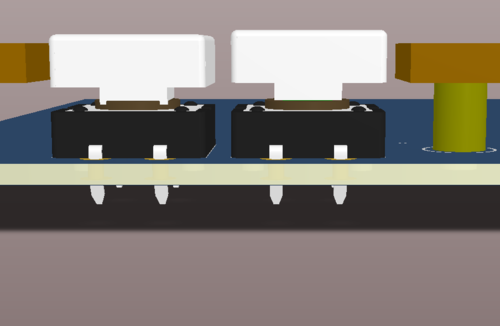

January 17, 2019 checked 3mm wood thickness combined with 5.8mm high brass standoffs

To check if the keys with keytops are high enough when I use 5.8mm high brass spacers, and 3mm thick wood, I made this virtual detail:

As you can see the height is fine, even when the button is pressed (left button is virtually pressed in above detail). As you can see the keytops now have rounded edges, like the real ones. The main picture of the page is also updated with these softer keytops, although the difference is small, it still looks nicer, and more "real". Unfortunately I see no way to put any text on the 3D rendered keytops, but I'm still happy with how this 3D rendered preview looks.