Decapping: Difference between revisions

mNo edit summary |

m (→First run) |

||

| (6 intermediate revisions by the same user not shown) | |||

| Line 7: | Line 7: | ||

}} | }} | ||

Decapping refers to the process of liberating a silicon die from the epoxy resin in which it is encased. This can be done in a number of ways, but the preferred method unfortunately involves digesting the encapsulant with fuming nitric acid. As | Decapping refers to the process of liberating a silicon die from the epoxy resin in which it is encased. This can be done in a number of ways, but the preferred method unfortunately involves digesting the encapsulant with fuming nitric acid. As its name suggests, this substance is just too nasty to keep on hand, so it's best produced on an as-needed basis. For those curious, I've written a short overview of the process below. Please note, this is not meant as a how-to. | ||

==Process== | ==Process== | ||

| Line 13: | Line 13: | ||

By reacting small amounts of potassium nitrate with concentrated sulphuric acid, and distilling from a suitably sized glass retort, even milliliter quantities of concentrated nitric acid can be produced with surprisingly little hassle. The use of a hot sand bath allows for a very controlled heating of the retort, which helps to keep the yield closer to theoretical maximum, and production of undesirable nitrogen oxides to a minimum. Acid with fewer dissolved oxides is also slightly more pleasant to work with, but even so it remains an awful, awful substance. Thankfully, just a few mL is ample for the purposes of decapping some IC's, and any acid that is left over at the end of the session is simply destroyed. All waste from the reaction, once neutralized, can be disposed of through regular means, with the exception of any waste that contains metal salts from a decapped device. | By reacting small amounts of potassium nitrate with concentrated sulphuric acid, and distilling from a suitably sized glass retort, even milliliter quantities of concentrated nitric acid can be produced with surprisingly little hassle. The use of a hot sand bath allows for a very controlled heating of the retort, which helps to keep the yield closer to theoretical maximum, and production of undesirable nitrogen oxides to a minimum. Acid with fewer dissolved oxides is also slightly more pleasant to work with, but even so it remains an awful, awful substance. Thankfully, just a few mL is ample for the purposes of decapping some IC's, and any acid that is left over at the end of the session is simply destroyed. All waste from the reaction, once neutralized, can be disposed of through regular means, with the exception of any waste that contains metal salts from a decapped device. | ||

The actual decapping is pretty straight-forward. With as much of the exposed metal pins trimmed off as possible | The actual decapping is pretty straight-forward. With as much of the exposed metal pins trimmed off as possible, a condemned integrated circuit is placed in a test tube, to which acid is then added. The epoxy is digested much faster with the addition of a little heat, and placing the tube in a warm sand bath is a convenient way to do this. Once the reaction settles down, you're left with a jet black sludge and (hopefully) a pristine die somewhere at the bottom of the tube. | ||

All parts of this process involve the release of some nitric acid fumes and/or nitric oxides, which are decidedly not good to breathe in. Considering the tiny volumes that we're working with here, the total amount of pollutants released into the atmosphere | All parts of this process involve the release of some nitric acid fumes and/or nitric oxides, which are decidedly not good to breathe in. Considering the tiny volumes that we're working with here, the total amount of pollutants released into the atmosphere does not compare unfavourably to NOx emissions from the tailpipe of a (volkswagen) diesel on its average commute, but the gases are of course more concentrated. | ||

==First run== | ==First run== | ||

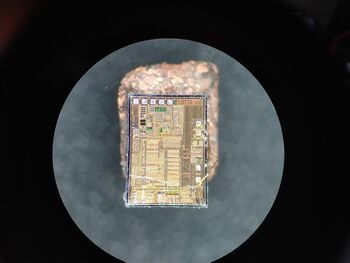

We bought some Dallas DS18B20 temperature sensors from Aliexpress, at a price that just seemed too good to be true. Upon inspection of the die inside, | We bought some Dallas DS18B20 temperature sensors from Aliexpress, at a price that just seemed too good to be true. Upon inspection of the die inside, suspicions of funny business were confirmed. Some clearly visible branding on the silicon itself indicates that these are actually a QTEK part. QTEK is a Chinese manufacturer that markets an 18B20 [https://lcsc.com/product-detail/Temperature-Sensors_7Q-TEK-QT18B20_C194239.html clone] under their own banner, but their parts clearly also end up in the hands of less scrupulous resellers, who are happy to pass them off as genuine. | ||

<gallery> | <gallery> | ||

| Line 27: | Line 27: | ||

</gallery> | </gallery> | ||

'''Do you have | '''Do you have an interesting IC that you wish to decap, then by all means contact me and I will include it in the next decapping session!!!''' | ||

Latest revision as of 16:46, 27 August 2019

| Project Decapping | |

|---|---|

| |

| Status | In progress |

| Contact | thomas |

| Last Update | 2019-08-27 |

Decapping refers to the process of liberating a silicon die from the epoxy resin in which it is encased. This can be done in a number of ways, but the preferred method unfortunately involves digesting the encapsulant with fuming nitric acid. As its name suggests, this substance is just too nasty to keep on hand, so it's best produced on an as-needed basis. For those curious, I've written a short overview of the process below. Please note, this is not meant as a how-to.

Process

By reacting small amounts of potassium nitrate with concentrated sulphuric acid, and distilling from a suitably sized glass retort, even milliliter quantities of concentrated nitric acid can be produced with surprisingly little hassle. The use of a hot sand bath allows for a very controlled heating of the retort, which helps to keep the yield closer to theoretical maximum, and production of undesirable nitrogen oxides to a minimum. Acid with fewer dissolved oxides is also slightly more pleasant to work with, but even so it remains an awful, awful substance. Thankfully, just a few mL is ample for the purposes of decapping some IC's, and any acid that is left over at the end of the session is simply destroyed. All waste from the reaction, once neutralized, can be disposed of through regular means, with the exception of any waste that contains metal salts from a decapped device.

The actual decapping is pretty straight-forward. With as much of the exposed metal pins trimmed off as possible, a condemned integrated circuit is placed in a test tube, to which acid is then added. The epoxy is digested much faster with the addition of a little heat, and placing the tube in a warm sand bath is a convenient way to do this. Once the reaction settles down, you're left with a jet black sludge and (hopefully) a pristine die somewhere at the bottom of the tube.

All parts of this process involve the release of some nitric acid fumes and/or nitric oxides, which are decidedly not good to breathe in. Considering the tiny volumes that we're working with here, the total amount of pollutants released into the atmosphere does not compare unfavourably to NOx emissions from the tailpipe of a (volkswagen) diesel on its average commute, but the gases are of course more concentrated.

First run

We bought some Dallas DS18B20 temperature sensors from Aliexpress, at a price that just seemed too good to be true. Upon inspection of the die inside, suspicions of funny business were confirmed. Some clearly visible branding on the silicon itself indicates that these are actually a QTEK part. QTEK is a Chinese manufacturer that markets an 18B20 clone under their own banner, but their parts clearly also end up in the hands of less scrupulous resellers, who are happy to pass them off as genuine.

Do you have an interesting IC that you wish to decap, then by all means contact me and I will include it in the next decapping session!!!