CNC plasma cutter: Difference between revisions

Jump to navigation

Jump to search

m (Woops, I'm a User of course) |

No edit summary |

||

| (26 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

{{Project | |||

|Name= CNC plasma cutter | |||

|Status=Initializing | |||

|Contact= Walter, [[User:Smeding|Smeding]], [[User:Gori|Gori]], [[User:Yotson|Yotson]], [[User:Semafoor|Semafoor]] | |||

}} | |||

After acquiring a [[Plasmasnijder|plasma cutter]] at the space, it seemed only logical to try and fabricate a CNC version eventually. | After acquiring a [[Plasmasnijder|plasma cutter]] at the space, it seemed only logical to try and fabricate a CNC version eventually. | ||

This goal is still a while away for now, but as always, we are full of Ideas and this is a convenient place to put them. | This goal is still a while away for now, but as always, we are full of Ideas and this is a convenient place to put them. | ||

== | == System overview == | ||

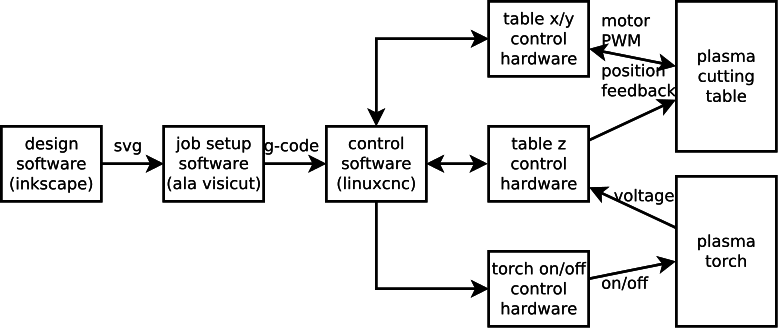

* | The diagram below shows the proposed system setup. | ||

* | |||

* | [[File:plasmacnc.svg]] | ||

From left to right: | |||

* design software (like inkscape) is used to design the shape to be cut and to export it as svg. | |||

* job setup software (unknown, but something like visicut) is used to position the shape and convert it to g-code. | |||

* linuxcnc (or possibly grbl) is used to "execute" the g-code through the control hardware. | |||

* the control hardware powers the motors of the cutting table and controls the plasma torch | |||

We're basing this project on an old X-Z traversing unit originally made for measuring air velocity distributions in wind tunnels at a metrology institute. The current motor controllers, however, seem to be made for a fixed speed and it's probably easiest to replace the electronics altogether. | |||

<gallery> | |||

File:X-Z_traverseerunit_front.jpg|X-Z traversing unit before any modifications | |||

File:X-Z_traverseerunit_stuurelektronika.jpg|Current control electronics with DC-motor controllers and Mitsubishi PLC | |||

</gallery> | |||

A Z-axis seems required to control the torch height. It won't need to move very far, quickly or precisely, though. | |||

== To-do list == | |||

# Decide how to control the machine. There seem to be two basic options: GRBL and LinuxCNC | |||

#* [[User:Smeding|Smeding]] knows a little bit about LinuxCNC and is willing to do some of the work | |||

# Design and build interface/driver hardware for motors and encoders | |||

#* [[User:Smeding|Smeding]] is willing to help with this | |||

#* [[Benadski]] has motor controller hardware that takes PWM as input. | |||

# Set up a PC that can withstand the general environment of the SparkShack (EMI, humidity, temperature) | |||

# Get basic motion control working so that the machine moves | |||

# Design and build interface hardware for the plasma torch, so it can be turned on and off. Will probably want voltage sensing for torch height control. | |||

#* [[User:Smeding|Smeding]] is willing to help with this, too | |||

# Add a third axis to the machine for torch height control | |||

# Put everything together -- implement the software side of things for torch height control and reading e.g. SVG files | |||

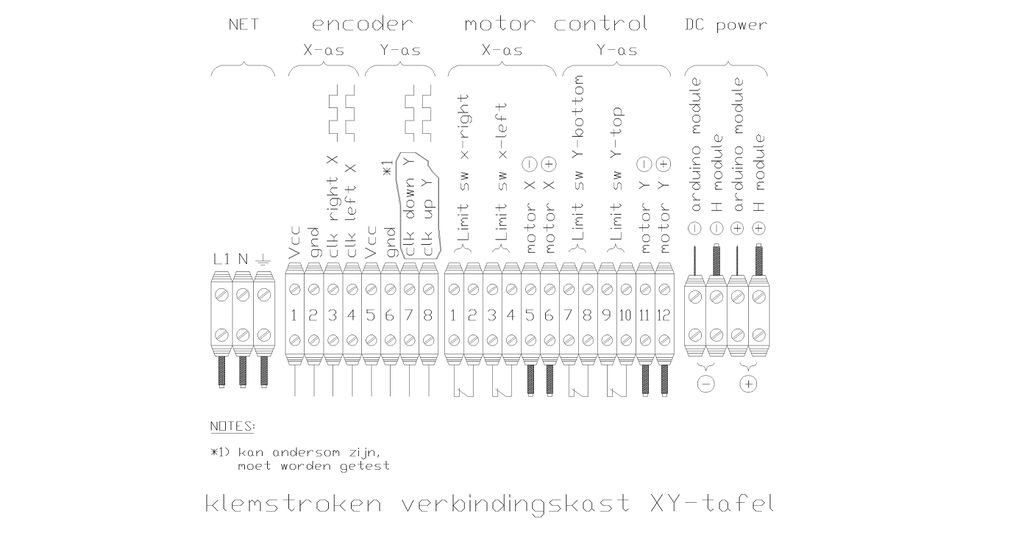

connection diagram: | |||

<br> | |||

[[File:XY-tafel connection diagram bewerkt.JPG|1024px]] | |||

<br> | |||

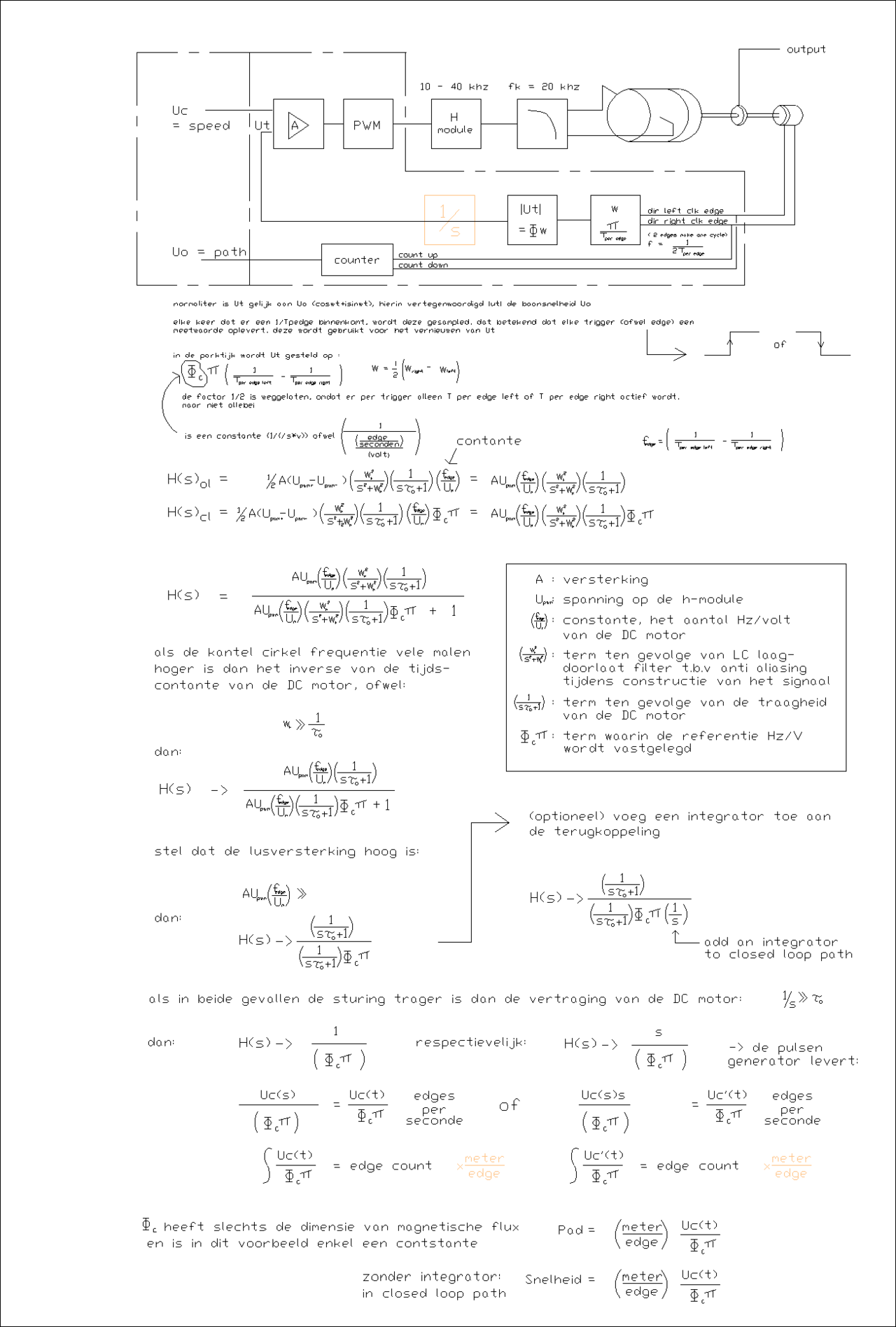

blokdiagram sturing plasmasnijder<br> | |||

<br> | |||

[[File:Blockdiagram sturing rev 2.1.PNG|1280px]] | |||

<br> | |||

Latest revision as of 01:43, 21 October 2015

| Project CNC plasma cutter | |

|---|---|

| Status | Initializing |

| Contact | [[Project Contact::Walter, Smeding, Gori, Yotson, Semafoor]] |

| Last Update | 2015-10-21 |

After acquiring a plasma cutter at the space, it seemed only logical to try and fabricate a CNC version eventually.

This goal is still a while away for now, but as always, we are full of Ideas and this is a convenient place to put them.

System overview

The diagram below shows the proposed system setup.

From left to right:

- design software (like inkscape) is used to design the shape to be cut and to export it as svg.

- job setup software (unknown, but something like visicut) is used to position the shape and convert it to g-code.

- linuxcnc (or possibly grbl) is used to "execute" the g-code through the control hardware.

- the control hardware powers the motors of the cutting table and controls the plasma torch

We're basing this project on an old X-Z traversing unit originally made for measuring air velocity distributions in wind tunnels at a metrology institute. The current motor controllers, however, seem to be made for a fixed speed and it's probably easiest to replace the electronics altogether.

A Z-axis seems required to control the torch height. It won't need to move very far, quickly or precisely, though.

To-do list

- Decide how to control the machine. There seem to be two basic options: GRBL and LinuxCNC

- Smeding knows a little bit about LinuxCNC and is willing to do some of the work

- Design and build interface/driver hardware for motors and encoders

- Set up a PC that can withstand the general environment of the SparkShack (EMI, humidity, temperature)

- Get basic motion control working so that the machine moves

- Design and build interface hardware for the plasma torch, so it can be turned on and off. Will probably want voltage sensing for torch height control.

- Smeding is willing to help with this, too

- Add a third axis to the machine for torch height control

- Put everything together -- implement the software side of things for torch height control and reading e.g. SVG files